SERVICES

We specialize in development of unique technologies that conventional industries are unwilling to take on

UNIQUE TECHNOLOGIES

-

Cavitation Peening

-

Controlled Geometry Abrasivejet Milling

-

Hyperbaric Testing

-

High Speed Ceramic Machining

-

Chemical Free Chrome Stripping & Selective Coating Removal

-

Precision 5-axis Machining & Hole Drilling

-

Downhole Energy Tooling

-

Nuclear Cleaning & Decommissioning Tooling

-

Laser Cladding of Wear Resistant Coatings

CUSTOMERS

-

US Navy (NAVAIR)

-

US Air Force

-

US Army

-

Missile Defense Agency

-

NASA

-

National Science Foundation

-

Pratt and Whitney Rocketdyne

-

Rolls-Royce

-

General Electric

-

Lockheed

-

Raytheon

-

ATK

-

Boeing

-

Baker-Hughes

-

Framatome

-

Sikorsky

-

W. L. Gore

-

General Atomic

-

CoorsTek

RESEARCH & DEVELOPMENT

Government and Commercial contract research to develop new technologies that address a range of complex manufacturing applications

PRODUCTION

Specialized in-house manufacturing services and advanced technologies delivered to our customers for production in their own facilities

ENGINEERING SERVICES

Contract engineering services, supplying customers with custom tooling, software and processes

Cavitation Peening

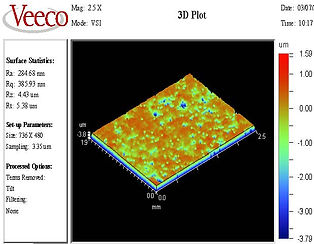

Cavitation peening is a new technology that can quickly generate high magnitude deep compressive stresses in metals and ceramics without roughening the surface of the part. It is used to improve fatigue resistance and increase the size of material flaw that can be tolerated in fatigue prone components. It was shown to significantly increase impact fracture damage resistance in brittle components. Hydraulic tubing peened by Ormond for the V-22 demonstrated increased fatigue life from less than 25,000 cycles to greater than 500,000 cycles. This low cost process is capable of creating residual stresses deeper than 0.040 inch and can be used to process very small stress-concentration features, such as between gear teeth and in thread roots. Cavitation peening does not require the use of shot of any kind but uses only a jet of high velocity fluid to generate shock waves and create residual stresses. It generates much deeper compression than is possible with shot peening and is approximately 100 times faster than laser shock peening. The cavitation peening intensity is easily controlled, by varying the process parameters.

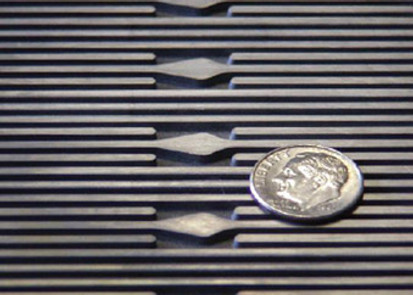

Controlled Geometry Waterjet Milling

The patented Ormond abrasive waterjet machining technology is used to mill controlled depth channels and pockets in challenging aerospace and high temperature materials. A proprietary software package makes it possible to mill complex shapes into contoured surfaces in materials such as nickel-cobalt alloys, refractory metals, ceramics and any steel alloy. This has been an enabling technology in several difficult aerospace, military and optical applications, making it possible for system developers to push the envelope with their designs.

Waterjet Rifling & NDT Inspection

Similar to line-of-site waterjet milling, Ormond has miniaturized this technology to perform controlled geometry milling on the inner bore of tubing. This method can be used to produce constant or variable diameter smooth bores from various starting conditions. Controlled geometry channels can also be produced at any given spacing, constant or variable twist rate, and constant or variable profile. Channels can start and stop at any point along the length of the tube bore. The technology was developed for a gun barrel rifling application but can easily be adapted to suit other purposes. Just as line-of-site waterjet milling, this process can be performed on conventionally difficult to machine materials, such as high temperature and corrosion resistant alloys, refractory metals, ceramics, and steel alloys. High accuracy inspection of pre-machined, in-process, and post-process conditions are critical to meeting tolerances and are thus an added benefit developed in tandem under this technology. These paired processes have been deployed on inside diameters ranging from 1/4" to over 6" to date. Army testing in various calibers has shown a greater than 5x improvement in barrel wear life, enabling further designed performance improvements.

High Speed Ceramic Machining

Conventional waterjets are not capable of providing satisfactory performance when machining some ceramics. Commercially available nozzles are limited by their wear resistance to abrasives that are aggressive enough to properly machine materials like alumina, boron carbide or silicon. However Ormond has developed a new ceramic composite nozzle that is 100 times more wear resistant than commercial nozzles when using abrasives that cut ceramics several times faster than commonly used garnet. This nozzle wear resistance is key because wear would otherwise degrade the machining process control in only minutes. Ormond waterjet milling rates in silicon carbide are more than 10 times greater than diamond grinding and do not generate damaging subsurface fractures.

Custom CNC Machines and Tooling

Commercial waterjet machine tool manufacturers sell high quality equipment for supporting common waterjet machining applications, but advanced applications often require specialized machines and tooling. Customers come to Ormond because commercially available machines don’t always meet their specific requirements. Single or multi-axis, large or small, close tolerance machines are built to meet each individual customer's specifications. The engineers at Ormond design and fabricate custom tooling and accessories to support the customer’s needs.

Professional CNC controllers are provided with these systems so customers can operate using commercially standard software whenever possible. Ormond supplies custom software and post processors to display inspection results and/or generate CNC code as needed. The major players in the waterjet machine tool market supply a standard listing of waterjet components and machine tools in order to address the needs of a broad mix of customers. Engineers at Ormond understand the needs of businesses that perform efficient, high-volume production for unique or specialized applications.